It does not matter how serious or how slightly we intend to work: it

seems that we are condemned to hard work without being able to

fulfill the goals we set out. We began to work on September 1st, thinking

in a new tail wheel, a pair of reinforcements for the metallical base frame,

a new exhaust jet tube, a new fuel tank and an electrical command board that

would allow us to get rid of the compressed air starting. What is more, we would arrive with time

sufficient to try a start during the Week of Technical Education, and surely we

would have time after the end of the regular classes period to make a thrust

meter although an elementally one. Still with the same work regime of

the previous year, we are the same workgroup!.

It does not matter how serious or how slightly we intend to work: it

seems that we are condemned to hard work without being able to

fulfill the goals we set out. We began to work on September 1st, thinking

in a new tail wheel, a pair of reinforcements for the metallical base frame,

a new exhaust jet tube, a new fuel tank and an electrical command board that

would allow us to get rid of the compressed air starting. What is more, we would arrive with time

sufficient to try a start during the Week of Technical Education, and surely we

would have time after the end of the regular classes period to make a thrust

meter although an elementally one. Still with the same work regime of

the previous year, we are the same workgroup!.

The certain thing is that we could not fulfill our aims not only by the

Technical Education Week, we could neither fulfill them by December 10th

(Anniversary of the first starting of the Derwent V turbojet), nor by

17th of the same month (Anniversary of the first start of the Marboré turbojet).

We hardly finished again at December 19th, a pair of

days before the end of regular classes period and without thrust meter...

Perhaps we were a little (too much) optimistic about the time that each one of

the proposed tasks would demand, but the unexpected

problems that we faced costed us precious days. And although a

little late, luckily we concluded them successfully. Next we

describe them by almost rigorous "difficulty degree":

The certain thing is that we could not fulfill our aims not only by the

Technical Education Week, we could neither fulfill them by December 10th

(Anniversary of the first starting of the Derwent V turbojet), nor by

17th of the same month (Anniversary of the first start of the Marboré turbojet).

We hardly finished again at December 19th, a pair of

days before the end of regular classes period and without thrust meter...

Perhaps we were a little (too much) optimistic about the time that each one of

the proposed tasks would demand, but the unexpected

problems that we faced costed us precious days. And although a

little late, luckily we concluded them successfully. Next we

describe them by almost rigorous "difficulty degree":

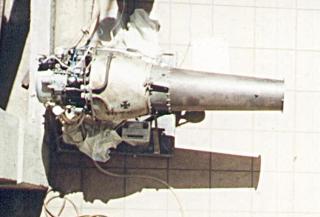

Exhaust jet tube

What to say about the piece that carefully studied in its form and unions

to be finished in three afternoons finally would demand us twelve complete

working days?. Here the problem was not the selection of the

material (2 millimeters thickness steel plate), it was our inexperience in

the cut, rolled, folded and assembly of it.

What to say about the piece that carefully studied in its form and unions

to be finished in three afternoons finally would demand us twelve complete

working days?. Here the problem was not the selection of the

material (2 millimeters thickness steel plate), it was our inexperience in

the cut, rolled, folded and assembly of it.

Previously we did the development of the tube in Autocad, the only easy task without problems. The cut of the steel plate had to be made with abrasive discs. Only this operation demanded us two complete days of work. We rolled and folded the tube in the School's Blacksmith workshop and to be able to remove the tube just rolled we had to disassemble the rolling machine...

And the first viewing of the finished work was really exasperating:

the "tube" was something deform from any point of view and the

hardness of the cold folded material made any manipulating or fitting attempt

almost impossible. We were advised several times to do a

hot work over it, but the lack of time and equipment made us discard the

idea. And we ended taking at least the triple time to do the necessary folding...

Then we had to make wood and steel molds to take it slowly to its almost final

form and to finish it, assemble it over the turbojet with a giant tool created for such aim.

It was not a smaller problem either doing with a manual drill 28

holes that will hold the exhaust jet tube to the turbojet. One thing is to bore tin

plate and another thing is to bore 2 millimeters thickness steel...

And the first viewing of the finished work was really exasperating:

the "tube" was something deform from any point of view and the

hardness of the cold folded material made any manipulating or fitting attempt

almost impossible. We were advised several times to do a

hot work over it, but the lack of time and equipment made us discard the

idea. And we ended taking at least the triple time to do the necessary folding...

Then we had to make wood and steel molds to take it slowly to its almost final

form and to finish it, assemble it over the turbojet with a giant tool created for such aim.

It was not a smaller problem either doing with a manual drill 28

holes that will hold the exhaust jet tube to the turbojet. One thing is to bore tin

plate and another thing is to bore 2 millimeters thickness steel...

We hope we won't need a new exhaust jet tube every six months!

Throttle

Another thing that produced incredible delays to us was to count with an adequate

command system to regulate the RPMs of the machine. We knew by '82 experience

that a bicycle brake cable command type was absolutely inadequate (In

Derwent V we had used synchronous electrical motors). And always by the

same reason (lack of time, resources and somebody among us that knew how to

make it fast...)

this solution was discarded by some other much more faster and economic that

would demand at most... ten days more!. At some moment it was

spoken to use stepping motors, and this was discarded at once

(same reasons as before). We studied the possibilities of a hydraulic driven

system, but the acquisition cost was simply prohibitive.

Then we tried to make our own system actuators. The results obtained would be more than

interesting if we had more time to develop them. A simple effect system

demonstrated to fail by the crushing of the plastic pipes that were used,

and one system of double effect (the most promising of the two) developed by

J. Radesca with cylinders made for compressed air was almost perfect but

it had a 20 millimeters stroke when we needed a 70 millimeters stroke. Between tests

and sometimes we returned to the "simple wire" command and ended with

a device that only a weight lifter could handle suitably. We had to begin again,

and this time with something that we commented often without too much conviction:

the use of a "wire" system similar to the first, but double (A push - pull

arranged system). It demonstrated

to be most than adequate, and even so it took us four days to make it work right.

Another thing that produced incredible delays to us was to count with an adequate

command system to regulate the RPMs of the machine. We knew by '82 experience

that a bicycle brake cable command type was absolutely inadequate (In

Derwent V we had used synchronous electrical motors). And always by the

same reason (lack of time, resources and somebody among us that knew how to

make it fast...)

this solution was discarded by some other much more faster and economic that

would demand at most... ten days more!. At some moment it was

spoken to use stepping motors, and this was discarded at once

(same reasons as before). We studied the possibilities of a hydraulic driven

system, but the acquisition cost was simply prohibitive.

Then we tried to make our own system actuators. The results obtained would be more than

interesting if we had more time to develop them. A simple effect system

demonstrated to fail by the crushing of the plastic pipes that were used,

and one system of double effect (the most promising of the two) developed by

J. Radesca with cylinders made for compressed air was almost perfect but

it had a 20 millimeters stroke when we needed a 70 millimeters stroke. Between tests

and sometimes we returned to the "simple wire" command and ended with

a device that only a weight lifter could handle suitably. We had to begin again,

and this time with something that we commented often without too much conviction:

the use of a "wire" system similar to the first, but double (A push - pull

arranged system). It demonstrated

to be most than adequate, and even so it took us four days to make it work right.

Thing to improve in 2001.

Electrical control board

Electrical control board

When we thought that after solving the accelerator problems everything was on the right road, we were again wrong. We had two basic problems with the electrical board: To find out a circuit that could replace in an effective way the lacking elements of the original one mounted on the airplane, and still worse; to find elements of zero cost acquisition that could drive the amperage produced in the starting. Everything would be mounted on what was left of a small broken table with their legs prolonged, over a surface work of corrugated cardboard. No. We were not so poor. We were offered a far better unit built by the School's Carpentry workshop, but since we supposed (and this time we were not wrong about it) that we would have to make many modifications which would finally affect the final aspect of something well done; we preferred to leave the good finish for the future.

We had to replace the auxiliary gears box by the assembly of the other turbojet because we verified that its auxiliary starter engine - power transmission system was not in good condition, this we didn't notice when doing the starting with compressed air.

Then we had to make an auxiliary starting resistance for the starting system

that would be used only in the first 8 seconds of the starting sequence to prevent

the gears box from breaking when the auxiliary electric motor is connected.

We decided to make it from nichrome wire and determined its necessary value experimentally.

In the shot it can be seen some of the

so many resistances that did not pass the test. But we also solved this problem.

Later the "definitive" electrical circuit was devised (number III) and we left as a last work

the wiring and connections before trying the start.

We received as donation cables and switches for the command board, ammeter and voltmeter for measure of

RPMs but we lost two days looking for some switch or mechanism that could

stand the 180 Ampere of the starting without problems (and something that

logically we did not have to pay...). As we did not find it, in the end

we tried with 15 Ampere switchs donated by the School's Electricity workshop.

And they worked!.

Then we had to make an auxiliary starting resistance for the starting system

that would be used only in the first 8 seconds of the starting sequence to prevent

the gears box from breaking when the auxiliary electric motor is connected.

We decided to make it from nichrome wire and determined its necessary value experimentally.

In the shot it can be seen some of the

so many resistances that did not pass the test. But we also solved this problem.

Later the "definitive" electrical circuit was devised (number III) and we left as a last work

the wiring and connections before trying the start.

We received as donation cables and switches for the command board, ammeter and voltmeter for measure of

RPMs but we lost two days looking for some switch or mechanism that could

stand the 180 Ampere of the starting without problems (and something that

logically we did not have to pay...). As we did not find it, in the end

we tried with 15 Ampere switchs donated by the School's Electricity workshop.

And they worked!.

The "Arrancamatic" needs a rethinking and a total reconstruction for 2001.

Thermocouple and exhaust gas temperature meter

Thermocouple and exhaust gas temperature meter

One of the things we worked on dead times whenever we did not have material to continue with the works was the thermocuople. Still we do not know why it failed in 1999, but after some tests it began to give life signals again. We changed four measure instruments, and as we did not trust any of the readings that we obtained after losing other two days we ended up doing what we had to do at first time: we took the assembly thermocouple - compensated cable - measurement instrument to the School's Ceramics workshop and we contrasted it against the indicator of one of its furnaces. Three test warming up and down, and the drawing of a "calibration curve" (Really a "contrast curve...) with the data acquired left us something more calmer about the behavior of the assembly.

Another thing to improve in the 2001.

Fuel tank

Few things (maybe none) as the fuel tank were made as they were

planned and without misfortunes. Even we were able to test our first ideas

with a wood scale model of real size of the finished device. Our goal was to

do something transferable to any site of the School and that allowed us a

fast change of the empty drum of 200 liters by another equal but full

merely by rotating the device 90 degrees over its back, unscrewing two bolts,

replacing the drum, screwing again the bolts, and rotating again 90 degrees the

device to its normal position.

Few things (maybe none) as the fuel tank were made as they were

planned and without misfortunes. Even we were able to test our first ideas

with a wood scale model of real size of the finished device. Our goal was to

do something transferable to any site of the School and that allowed us a

fast change of the empty drum of 200 liters by another equal but full

merely by rotating the device 90 degrees over its back, unscrewing two bolts,

replacing the drum, screwing again the bolts, and rotating again 90 degrees the

device to its normal position.

We need to make a fuel level meter for it in 2001

Metallic base frame

Metallic base frame

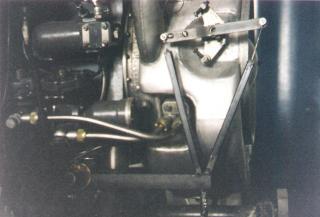

Perhaps the simplest work that we faced in 2000 was the reinforcement of the existing metallic base frame with the aim of being able to stand the stress put over it by the turbojet at its maximum possible RPMs (and thus maximum thrust), basically "stiffening" the assembly with "diagonals" added over the existing base corners. On middle - December the support for the (still nonexistant) thrust meter and the batteries' board was added as well.

We must do a better completion and painting in 2001...

Base tail wheel

Once ended the works of reinforcement of the frame a new support

for the tail wheel was made. The used one until now showed fatigue signs

in the joints and the increase of weight by the inclusion of

the batteries in the base and the reinforcements was only going

to make things worse. We hope that this one is the definitive

version. (And three are going...)

Once ended the works of reinforcement of the frame a new support

for the tail wheel was made. The used one until now showed fatigue signs

in the joints and the increase of weight by the inclusion of

the batteries in the base and the reinforcements was only going

to make things worse. We hope that this one is the definitive

version. (And three are going...)

So in the 19th morning we dedicated ourselves to follow the wiring

in a calmer way and, we "discovered" that the same switch of the previous

day continued with the same wrong wiring. After joking with the (i)rresponsable person

that had made the mistake twice, we made some tests replacing the starting system

by a fixed resistance that allowed us to have the security that everything was

working OK and we preferred to delay the starting until 4:00 PM, since several

of the members of the workgroup were absentees.

So in the 19th morning we dedicated ourselves to follow the wiring

in a calmer way and, we "discovered" that the same switch of the previous

day continued with the same wrong wiring. After joking with the (i)rresponsable person

that had made the mistake twice, we made some tests replacing the starting system

by a fixed resistance that allowed us to have the security that everything was

working OK and we preferred to delay the starting until 4:00 PM, since several

of the members of the workgroup were absentees.

At 6:50 PM we decided to measure the charge state of the batteries

thinking more about December 20th than in another thing. And to

carry out the measurements there was no other way than initiating

the starting sequence by three seconds and to cut it off. As before three

seconds we listened how the primary ignition system had activated,

and the results of the measurement were good; we decided on the fly to

try the starting again.

At 6:50 PM we decided to measure the charge state of the batteries

thinking more about December 20th than in another thing. And to

carry out the measurements there was no other way than initiating

the starting sequence by three seconds and to cut it off. As before three

seconds we listened how the primary ignition system had activated,

and the results of the measurement were good; we decided on the fly to

try the starting again.

With each person in its place, and Jorge Radesca in the command board; at

6:52 hs. we began the starting sequence and this time after ending

it the Marboré was running by its own means. After obtaining

the RPMs stable regime we verified that we had reading of

pressure oil in the pressure gauge (2 kgf/cm2), reading of indirect

temperature with thermocuople (380 °C) and indirect RPMs reading

with the AC generator used as tachometer (~6 000 RPM).

With each person in its place, and Jorge Radesca in the command board; at

6:52 hs. we began the starting sequence and this time after ending

it the Marboré was running by its own means. After obtaining

the RPMs stable regime we verified that we had reading of

pressure oil in the pressure gauge (2 kgf/cm2), reading of indirect

temperature with thermocuople (380 °C) and indirect RPMs reading

with the AC generator used as tachometer (~6 000 RPM).

As we counted on a minimum oil level, and perhaps a fuel not so

adequate for what was required; we decided after one minute of running to

stop the turbojet, because in addition the values seen in

the instruments were so low compared with those of the maintenance

manual that we thought the instruments were not working well... (Note:

this we would confirm one year later!. See

As we counted on a minimum oil level, and perhaps a fuel not so

adequate for what was required; we decided after one minute of running to

stop the turbojet, because in addition the values seen in

the instruments were so low compared with those of the maintenance

manual that we thought the instruments were not working well... (Note:

this we would confirm one year later!. See  And like the previous year, the cut off fuel valve continued to be

badly placed and the turbojet just stopped when it exhausted the

fuel that was left in the feeding pipes.

And like the previous year, the cut off fuel valve continued to be

badly placed and the turbojet just stopped when it exhausted the

fuel that was left in the feeding pipes.

This time our photographer (Alejandro Flagel, the same as the last year) was really

inspired, capturing a remarkable sequence of the starting.

This time our photographer (Alejandro Flagel, the same as the last year) was really

inspired, capturing a remarkable sequence of the starting.

The 2001 will not find us unprepared and for the many

details that we must polish we count on the promise of aid of more

people than those that already helped us in 2000 and who we feel forced to

mention, so that people out of the project can catch some of its nature.

We have several funny stories generated

throughout the work, but we think that the first prize is won by the turbine oil

tin that made the trip Rosario - Buenos Aires, Buenos Aires - Rosario because

as the people who did the delivery said they could not find anyone to receive

it in the door of the School... And at this moment we know that the

tin is repeating the same journey again. Will there be this time a person to

receive it?. Will Krause School be at the same address or it will be changed with unknown destiny?.

Do not loose the "Thus we did in 2001"!...

The 2001 will not find us unprepared and for the many

details that we must polish we count on the promise of aid of more

people than those that already helped us in 2000 and who we feel forced to

mention, so that people out of the project can catch some of its nature.

We have several funny stories generated

throughout the work, but we think that the first prize is won by the turbine oil

tin that made the trip Rosario - Buenos Aires, Buenos Aires - Rosario because

as the people who did the delivery said they could not find anyone to receive

it in the door of the School... And at this moment we know that the

tin is repeating the same journey again. Will there be this time a person to

receive it?. Will Krause School be at the same address or it will be changed with unknown destiny?.

Do not loose the "Thus we did in 2001"!...